Understanding Flexible High-Frequency PCBs

At the intersection of flexibility and high-frequency operation, these PCBs are critical for devices where space and performance are at a premium. Unlike rigid PCBs, flexible high-frequency boards can bend and fold, accommodating unique design constraints and improving resilience against mechanical stress.

Materials and Components for High-Frequency PCBs

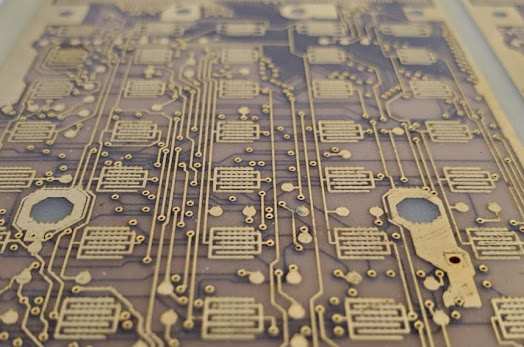

For high-frequency flexible PCBs, material selection is critical due to the unique demands of maintaining signal integrity and flexibility simultaneously. Here's a closer look at some specific flexible materials ideally suited for high-frequency PCB applications:

- Liquid Crystal Polymer (LCP): LCP is a top choice for high-frequency flexible PCBs due to its excellent electrical properties, such as a low and stable dielectric constant and loss tangent, which are crucial for minimizing signal loss at high frequencies. LCP's low moisture absorption ensures consistent performance even in varying environmental conditions. It's particularly favored in applications where precision and performance are paramount, such as in aerospace, telecommunications, and medical devices.

- Polyimide (PI): PI is renowned for its thermal stability and mechanical endurance, making it suitable for applications that experience extreme temperatures or require robust physical properties. While its electrical properties are not as optimized for high-frequency applications as LCP, PI's versatility and reliability make it a strong contender, especially in environments where durability is critical.

- Polytetrafluoroethylene (PTFE): Although more commonly associated with rigid PCBs, there are flexible versions of PTFE available. PTFE stands out for its outstanding electrical properties, including an exceptionally low dielectric constant and loss tangent, making it ideal for ultra-high-frequency applications. However, it's worth noting that PTFE can be challenging to manufacture and may require special treatment to bond with other materials effectively.

- Thermoplastic Polyurethane (TPU): While not as commonly used for high-frequency applications, TPU offers significant flexibility and durability, making it a potential choice for applications where the PCB may undergo frequent bending or twisting. However, its electrical properties may not be as optimized for high-frequency performance as those of LCP or PTFE.

When selecting a material for a high-frequency flexible PCB, it's essential to consider the specific requirements of your application, including the frequency range, environmental conditions, mechanical stresses, and manufacturing considerations. LCP and PTFE are generally preferred for their superior electrical performance in high-frequency applications, while PI and TPU might be selected for their mechanical properties and versatility in various environments.

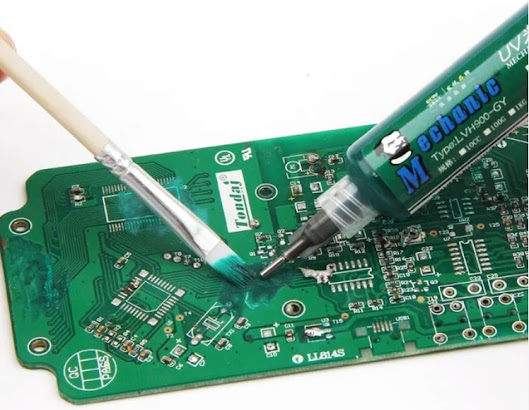

For conductors, copper in PCB is often chosen for its excellent electrical conductivity. However, at high frequencies, the skin effect can cause signals to propagate near the surface, necessitating careful consideration of conductor thickness and surface treatment.

Components must be selected not only for their performance but also for their compatibility with the flexible substrate and the unique challenges of high-frequency operation. This includes considerations for minimizing parasitic capacitances and inductances, which can significantly impact performance at high frequencies.

Design Considerations for Flexible High-Frequency PCBs

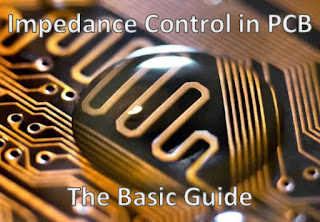

Impedance control is more than a guideline; it's a necessity. The impedance of traces must be carefully calculated and controlled, considering the substrate material, trace geometry, and surrounding environment.

Signal integrity is paramount. Strategies to minimize crosstalk and ensure clean signal propagation include careful trace routing, maintaining consistent trace widths, and using ground planes effectively to shield high-speed signals.

The PCB Thermal Management is also a key concern. High-frequency components can generate significant heat, and flexible PCBs often have limited thermal dissipation capabilities compared to their rigid counterparts. Strategies include using thermal vias, selecting heat-tolerant materials, and designing for adequate air flow.

Best Practices and Innovative Solutions

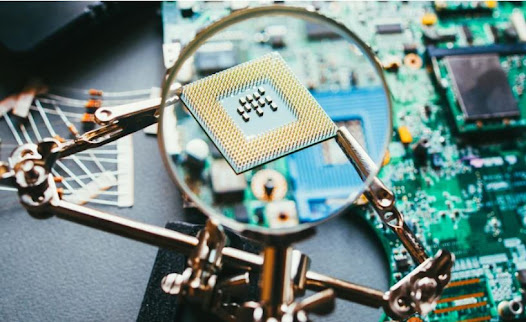

Simulation and testing are your best allies. High-frequency simulation tools can predict issues like impedance mismatches and signal reflection before they become costly production errors.

Innovative solutions, such as embedding passive components within the PCB substrate, can save space and improve signal integrity. Utilizing microvias and advanced via structures can enhance connectivity and reduce signal path lengths, critical for maintaining signal integrity at high frequencies.

Conclusion

Designing flexible high-frequency PCBs is a challenging yet rewarding endeavor, requiring a deep understanding of materials, signal behavior, and innovative design practices. By embracing these challenges and staying informed of the latest advancements, designers can push the boundaries of what's possible in modern electronics.