Flex circuit boards, also known as flexible PCBs, These versatile components are essential in modern devices where space and weight are limited, providing outstanding flexibility and durability compared to traditional rigid PCBs. This technology enables designers to push the boundaries of electronics design, creating more compact, lightweight, and complex devices that meet the evolving demands of today's tech-driven world.

In this blog, we will delve into the intricacies of flexible PCBs, examining the best materials for use, particularly focusing on polyimide and its optimal thickness for various applications. We'll explore why certain surface finishes are preferred and discuss stackup considerations that can significantly influence both performance and cost. Our discussion will also cover the durability of these boards, the critical IPC standards governing their quality, challenges faced during production, cost-effective manufacturing strategies, and the environmental impacts associated with their production.

Through this comprehensive guide, electronics engineers, PCB designers, and supply chain professionals will gain insights into making informed decisions about flexible PCBs, ensuring they choose the right materials, designs, and manufacturing processes to meet their project requirements effectively and efficiently.

Flexible PCB Materials and Design Considerations

A: Materials Used in Flex PCBs

Flexible PCBs require materials that can withstand extreme bending and folding without compromising the integrity of the circuit. The choice of materials not only affects the performance but also the manufacturability and longevity of the flex circuit. Among various materials available, polyimide stands out due to its exceptional thermal stability, chemical resistance, and flexibility.

Polyimide Flex PCBs:

Polyimide (PI) is the material of choice for most flexible PCB applications due to its robust performance in harsh environments. It is known for its excellent heat resistance — capable of operating in temperatures as high as 400 degrees Celsius — and its impressive mechanical properties. These characteristics make polyimide ideal for dynamic or high-temperature applications, including aerospace, automotive, and consumer electronics.Thickness Variations:

- 25um Polyimide: Often used in very flexible, high-density applications where the space is at a premium. It offers superior flexibility, making it ideal for intricate designs that require tight bending capabilities.

- 75um Polyimide: This thickness is a balanced option, providing a good mix of flexibility and mechanical strength, suitable for both dynamic and static applications.

- 100um Polyimide: Opted for projects requiring increased mechanical strength and durability. While less flexible than its thinner counterparts, it is beneficial in applications where minimal bending is involved.

The thickness choice directly impacts the cost—the thicker the polyimide, the more expensive the PCB and reducing of bending ratio. Designers must balance cost with performance requirements, considering how the board will be used in the final product.

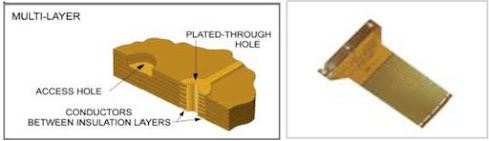

B: Flexible PCB Stackup and Design

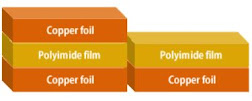

Stackup Configuration:

The stackup — the arrangement of insulating layers and conductive circuits in a PCB — is crucial in determining the board's overall performance. In flexible PCBs, the stackup must be designed to maximize the flexural endurance without sacrificing electrical integrity.

Single-Layer Flex: Consists of a single conductor layer on a flexible dielectric film, ideal for static applications where minimal bending occurs.

Double-Layer Flex: Two conductive layers with an insulating layer in-between, suitable for dynamic applications where the board may experience frequent bending.

Multilayer Flex: Multiple conductive layers separated by insulating materials, used in highly complex circuits requiring robust electrical performance and minimal space.

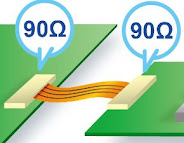

C: Impedance Control Techniques:

Controlling impedance is critical in flexible PCBs to ensure reliable signal integrity across the circuit. Techniques include:

- Precise control of trace width and spacing.

- Consistent dielectric material properties.

- Use of shielding layers to reduce external noise interference.

Cost Considerations:

Design complexity and material choice significantly impact the cost. For instance, multilayer flex PCB are more expensive due to their complex manufacturing processes. Designers must consider the trade-offs between performance, durability, and cost to optimize the board for both functionality and budget.

Flex PCB Durability and Standards

A. Durability Factors of Flexible PCBs

Durability is a paramount concern in the design and manufacture of flexible PCBs. The very flexibility that makes these boards so valuable also introduces unique challenges in ensuring they can withstand repeated bending and harsh operating conditions.

Key Durability Factors:

- Material Selection: As previously discussed, polyimide is favored for its high thermal stability and mechanical endurance. The choice of adhesive material, which bonds the conductive layers to the substrate, also plays a critical role. It must maintain its adhesive properties under thermal stress and repeated flexing.

- Copper Type: The type of copper used affects flexibility and durability. Rolled annealed (RA) copper is softer and more malleable, making it better suited for applications where the PCB will undergo extensive bending. Electrodeposited (ED) copper, though stiffer, is often used in applications requiring finer line widths.

- Through-Hole Plating: Reliable through-hole plating techniques are crucial for maintaining electrical continuity, especially in flex areas where mechanical stress is concentrated. Poor plating can lead to failures in electrical connections under stress.

Testing Procedures:

To ensure the durability of flexible PCBs, several testing procedures are employed:

- Bend Testing: Simulates the bending and flexing that the board will endure during its operational life.

- Thermal Testing: Assesses how well the board withstands temperature extremes and thermal cycling.

- Pull and Peel Tests: Measure the strength of adhesion between layers and the robustness of the surface mount components.

These tests help manufacturers identify potential failure points and improve board design and material selection to enhance durability.

B. IPC Standards for Flex Circuits

The IPC 6013 standard governs the performance and quality requirements for flexible printed boards. Adherence to this standard is crucial for ensuring that flexible PCBs meet the rigorous demands of various applications.

Key Aspects of IPC 6013:

- Class 1, 2, and 3 Requirements: Defines the criteria for different levels of performance, from general electronic products (Class 1) to high-reliability military and aerospace applications (Class 3).

- Material and Conductor Thickness: Specifies acceptable materials and minimum conductor thicknesses based on the application’s complexity and reliability needs.

- Testing and Acceptance Criteria: Outlines the required tests for validating the integrity and functionality of flex circuits under different operational stresses.

Compliance with these standards not only ensures product reliability but also enhances the manufacturer's credibility in the market, making it a crucial consideration for designers and engineers in the industry.

Challenges in Flexible PCB Production

Flexible PCB manufacturing involves distinct challenges that differ significantly from those encountered in traditional rigid PCB production. Addressing these issues requires specialized techniques, innovative materials, and a deep understanding of flex circuit design intricacies.

Common Production Challenges:

- Handling and Assembly: Due to their inherent flexibility, handling flex circuits without causing damage or deformation can be challenging. Automated assembly processes need to be carefully calibrated to avoid excessive stress on the boards.

- Alignment and Registration: During multilayer flex PCB fabrication, maintaining precise alignment of the layers is critical, especially given the material's tendency to stretch and contract. Misalignment can lead to functional failures and reduced reliability.

- Miniaturization: As devices become smaller, flex PCBs need to accommodate tighter bends and more compact configurations, which can complicate the manufacturing process and increase the risk of mechanical stress failures.

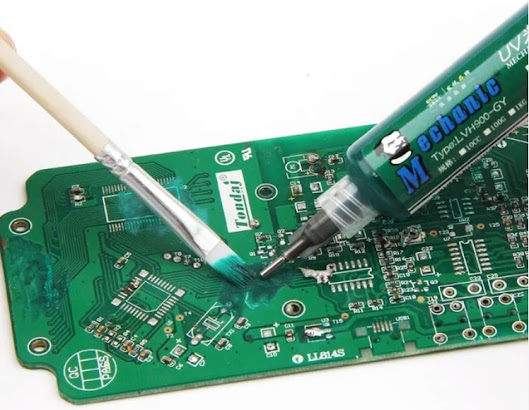

Surface Finish Options:

Choosing the right surface finish is crucial for enhancing the solderability and reliability of flex circuits. The surface finish protects the copper from oxidation and provides a solderable surface when connecting components.

- ENIG (Electroless Nickel Immersion Gold): Provides a flat surface and is suitable for fine-pitch components, making it a popular choice for high-density flex circuits.

- OSP (Organic Solderability Preservatives): A cost-effective option that offers good solderability but may not be as robust as other finishes for repeated flexing.

- Immersion Tin or Silver: These finishes offer excellent solderability and maintain a flat surface, but they can be prone to tarnishing and are less durable under thermal stress.

Technological Solutions:

To overcome these challenges, manufacturers employ various advanced techniques:

- Laser Direct Imaging (LDI): Improves alignment accuracy by allowing for precise and adaptable pattern creation, essential for the high-density requirements of modern flex circuits.

- Automated Optical Inspection (AOI): Ensures quality control by detecting and correcting defects early in the manufacturing process.

- Use of Stiffeners: Adding stiffeners in strategic areas can provide additional support during assembly and use, reducing stress on vulnerable parts of the flex circuit.

Cost-Effective Solutions for Flex PCB Manufacturing

Strategies to Reduce Manufacturing Costs:

- Design Optimization: By optimizing the design for manufacturability, manufacturers can reduce waste and increase production efficiency. This involves minimizing the use of wide traces and large pad sizes when not necessary, and strategically placing components to reduce the total number of layers needed.

- Material Selection: Choosing the right materials from the start can lead to significant cost savings. For example, selecting a slightly thicker polyimide may increase material costs but can reduce processing steps and improve yield by enhancing durability.

- Volume Production: Leveraging economies of scale by producing larger volumes can decrease the unit cost significantly. Planning production runs to maximize panel utilization also reduces waste and lowers the cost per unit.

Case Studies and Examples:

Influence of Design Complexity on Costs:

- Complexity of the Design: Higher complexity generally leads to increased costs due to more material layers and additional processing steps. Simplifying the design where possible can lead to substantial cost savings.

- Technology Integration: Advanced manufacturing technologies such as laser etching and automated placement machines can initially increase capital costs but pay off in the long run by improving accuracy, reducing waste, and speeding up production.

Choosing the Right Flex Circuit Manufacturer

Selecting a manufacturer for flexible PCBs is a critical decision that can significantly affect the quality, reliability, and overall success of your project. It requires careful consideration of various factors to ensure that the chosen supplier can meet your specific needs and standards.

Criteria for Choosing a Manufacturer:

Certifications and Compliance: Look for advanced manufacturers that adhere to industry standards and hold relevant certifications, such as ISO 9001 for quality management systems and IPC 6013 for specific flex PCB requirements. These certifications are indicators of the manufacturer’s commitment to quality and consistency.

Manufacturing Capabilities: Assess the technological capabilities of the manufacturer, including their ability to produce various flex PCB types, such as single-sided, double-sided, and multilayer flex circuits. Check for advanced manufacturing processes that can handle the specific requirements of your design, such as precision laser cutting and automated optical inspection systems.

Experience and Reputation: Consider the manufacturer’s track record and industry reputation. Look at reviews, case studies, and testimonials from other customers, particularly those in similar industries or with similar application requirements. Experience in handling complex and high-reliability flex circuits can be a significant advantage.

Supply Chain Robustness: Evaluate the robustness of the manufacturer’s supply chain, including material sourcing, lead times, and their ability to handle fluctuations in demand. A reliable supply chain is crucial for meeting project timelines and avoiding costly delays.

Cost Structure: While cost should not be the sole deciding factor, it is important to understand the pricing structure of the manufacturer. Ensure that the cost aligns with the budget constraints of your project without compromising the quality or performance of the flex circuits.

Support and Communication: Good communication is key to any successful partnership. Choose a manufacturer who provides clear and consistent communication throughout the design and production process. Support services such as design assistance, prototyping, and after-sales support are valuable services that can greatly enhance the manufacturing experience.

Tips on Vetting Potential Suppliers:

- Request Samples: Obtain samples of the manufacturer’s previous work to evaluate the quality and compatibility with your needs.

- Visit the Facility: If possible, visit the manufacturing facility to get a firsthand look at their operations and processes.

- Ask for References: Speak to current or past customers to gain insights into their experiences with the manufacturer.

Environmental Impact of Flexible PCB Manufacturing

The manufacturing of flexible PCBs, like many industrial processes, has a significant environmental footprint. Awareness and efforts towards minimizing this impact are crucial, as they not only comply with regulatory standards but also appeal to the growing consumer and corporate demand for environmentally responsible products.

Key Environmental Concerns:

- Use of Hazardous Chemicals: The production of flex PCBs involves various chemicals, particularly in the etching and plating processes, which can be harmful if not managed properly. Chemicals such as copper sulfate used in plating and various solvents in cleaning processes need careful handling and disposal.

- Waste Production: Flex PCB manufacturing generates solid and liquid waste, including metal scraps, used chemicals, and excess polyimide material. Proper waste management procedures are essential to minimize environmental harm.

- Energy Consumption: The production process is energy-intensive, especially in high-precision manufacturing tasks like laser cutting and automated inspection. Optimizing energy use and sourcing renewable energy can significantly reduce the carbon footprint.

Sustainable Practices in Manufacturing:

- Recycling and Reuse: Implementing recycling programs for metal scraps and other recyclable materials can significantly reduce waste. Some advanced manufacturers are exploring ways to reuse polyimide and other materials in new production cycles.

- Lean Manufacturing: Adopting lean manufacturing principles can help reduce waste and improve efficiency. This includes minimizing unused materials, optimizing production processes to use less energy, and reducing the overall waste generated.

- Eco-friendly Material Alternatives: Research into alternative materials that have a lower environmental impact than traditional polyimide is ongoing. Bio-based and recyclable polymers are being considered as potential substitutes that can provide similar performance with less environmental burden.

Future Trends and Innovations:

- Technological Advancements: Advances in manufacturing technology that increase yield and efficiency while reducing waste and energy consumption are likely to continue. Automation and improved process control can lead to more sustainable manufacturing practices.

- Regulatory Compliance: Compliance with environmental regulations is not just about avoiding penalties; it's also about leading the industry towards more sustainable practices. Manufacturers who proactively exceed compliance requirements can improve their market position and brand reputation.

- Consumer Demand: As consumers and businesses become more environmentally conscious, they demand greener products. Manufacturers that can demonstrate sustainable manufacturing practices and the environmental friendliness of their products have a competitive edge.

Conclusion

Throughout this detailed exploration of flexible PCBs, we have uncovered the complexities and innovations driving this crucial component of modern electronics. From the selection of materials like polyimide with varying thicknesses tailored to specific applications, to the intricate designs of stackup configurations ensuring optimal performance, flexible PCBs are at the forefront of technological advancement.

We delved into the crucial aspects of durability and adherence to IPC standards, highlighting how these factors ensure reliability and consistency in flex circuit board manufacturing. The challenges faced in production, particularly in handling, alignment, and miniaturization, were also discussed, alongside technological solutions that enhance quality and efficiency.

Cost-effective manufacturing strategies are vital for maintaining competitiveness in the industry. By optimizing design, selecting appropriate materials, and scaling production, manufacturers can significantly reduce costs without sacrificing quality. Selecting the right manufacturing partner, one that aligns with technical requirements and values, is essential for the successful implementation of flex PCBs in any project.

Moreover, we addressed the environmental impacts associated with flexible PCB manufacturing. Emphasizing sustainable practices, from waste management to the adoption of eco-friendly materials, is not just a regulatory compliance issue but a critical component of future industry standards. As the demand for greener products increases, manufacturers who lead in sustainability will likely lead the market.

Looking Forward:

The future of flexible PCB technology is bright, with ongoing advancements in materials science, manufacturing processes, and environmental sustainability set to further revolutionize this field. As electronic devices continue to evolve towards more compact and complex designs, the flexibility, durability, and efficiency offered by flex PCBs will become increasingly crucial.

For engineers, designers, and decision-makers in the electronics industry, understanding these aspects of flexible PCBs is essential. It ensures not only the functionality and reliability of their products but also their competitiveness and compliance with evolving environmental standards. As we move forward, the continuous innovation and improvement in flexible PCB manufacturing will undoubtedly open new horizons for electronic applications, making what seems complex today, standard tomorrow.