Section 1: Understanding Multilayer Rigid-Flex PCBs

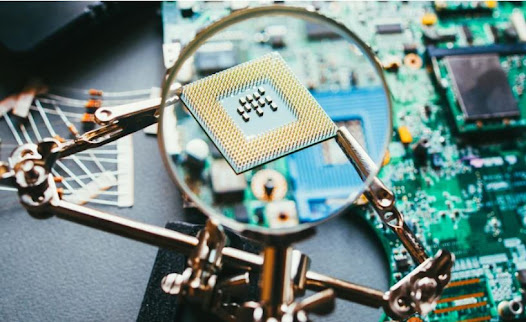

- Definition and overview of Multilayer Rigid-Flex PCBs

- Historical development and its growing relevance in modern electronics

- Comparison with traditional PCBs highlighting the added advantages of flexibility and space efficiency

Section 2: Design Considerations for Multilayer Rigid-Flex PCBs

- Material selection for optimum performance and durability

- Key design parameters including layer count, bend radius, and interconnection strategies

- Addressing thermal management in rigid-flex configurations

Section 3: The Manufacturing Process

- Step-by-step breakdown of the Multilayer Rigid-Flex PCB manufacturing process

- Challenges and solutions in the fabrication and assembly stages

- Quality control measures and testing protocols

Section 4: Applications of Multilayer Rigid-Flex PCBs

- Exploration of industries and devices where Multilayer Rigid-Flex PCBs are revolutionizing design paradigms

- Case studies highlighting the impact of these PCBs in sectors like aerospace, medical devices, and wearable technology

Section 5: Future Trends and Innovations

- Emerging technologies influencing the design and use of Multilayer Rigid-Flex PCBs

- The role of 3D printing and AI in advancing PCB design

- Predictions for the future trajectory of Rigid-Flex PCB technology

Section 6: The Stack Structure for Mass Production

- The configuration of rigid and flexible layers should be optimized for performance and manufacturability. Proper layer stack-up can also help in Interconnect Reliability, heat dissipation, signal integrity and so on...

Conclusion:

The journey through the world of Multilayer Rigid-Flex PCB design illustrates its significance in pushing the boundaries of electronic design. As technologies advance, understanding and mastering the nuances of Rigid-Flex PCBs will be crucial for designers aiming to innovate and excel in the dynamic landscape of electronics.